Process

Vendor Management System

Powerline Micro Electronics suppliers are formally selected and continually evaluated. New suppliers are selected after careful evaluation and successful completion of Powerline’s vendor application process.

We thoroughly quality every vendor’s reputation, performance and operations before adding them to our approved vendor list.

Our suppliers must continuously meet our quality standards to remain on our approved vendor list, high quality sources mean high quality products.

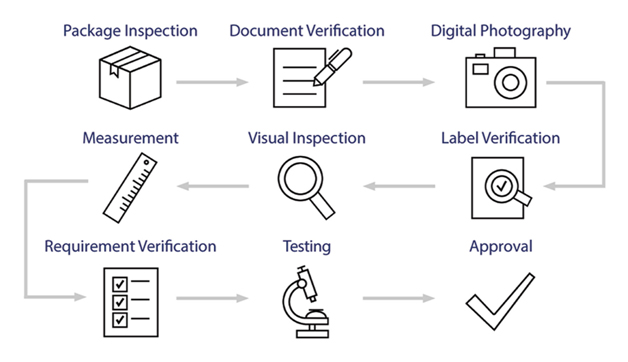

Inspection Process

Powerline quality inspectors are trained to identify counterfeit and substandard components. Based on years of knowledge surrounding quality assurance and counterfeit detection and prevention, our inspection process includes careful examination of parts from the outer packaging inward.

We initially so a Package Inspections to ensure that damage was not done to the shipping process, we check all documents to correlate with our clients purchase order, the we implement Digital Photography to maintain records of each lot.

Then we measure and perform a Visual Inspection, Label Verification to ensure correct part number, date code, country of origin and quantity.

We then attached a requirement Verification certificate to each lot.

If require we offer testing and then get our approval seal.