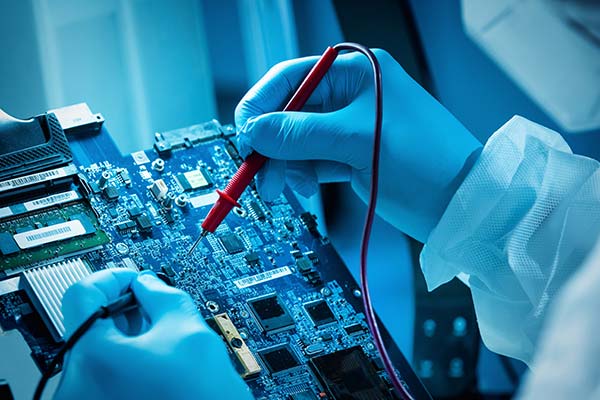

Counterfeit

Powerline in-house counterfeit detection is provisioned with the most advanced in-house tools to verify component authenticity. With destructive, non-destructive, and custom testing solutions available, the integrity of your parts will never be in question.

Sizing discrepancies

powerline measures the component height, length and width and then comparing these to the manufacturer’s specifications can give an indication that the part is genuine. If the measurements don’t match the manufacturer’s specifications, or there are variances across the batch you have received, then further investigation would be required

Marking authenticity

Blacktopping is a common technique used by counterfeiters which involves a thin layer of blacktopping material to cover the original part numbers and details. This is then re-printed with false markings in order to purposefully present the part as something that it isn’t. Arguably blacktopping is one of the most common techniques used by counterfeiters. This is obviously a cause for concern as the part you receive may be completely different to the part you ordered.

So how do you test for marking authenticity? Powerline test is to use an Acetone wash which is applied to the surface of a component helping to remove false printing or reveal the remnants of previous markings.

X-Ray inspection

Powerline offers X-Ray inspection is a technique to examine the inner workings of the component. X- Ray can be used to show evidence of counterfeiting by highlighting the die, wire bonds and any possible signs of delamination. Why is this important? Well, by examining the internals and comparing them to manufacturer specifications or controlled images of authentic parts, you will be able to determine whether the part is genuine.

Electrical Testing

Powerline offers electrical testing on suspect components and can give you a better idea of whether the part is genuine or not by comparing the results to the tolerances recorded by the manufacturer. If the results are significantly different to the industry specifications, then further investigation would be required.

Decapsulation

If the other checks mentioned above are not conclusive, or our technicians still have concerns over the authenticity of a part, it may be necessary to carry out decapsulation or ‘de-lidding’ of a sample component.

There are various techniques to carry out this process, often involving an acid solution, which therefore makes the process destructive. However, once this process is complete you can see the inner workings of a part using a high-powered microscope to visually inspect and verify factors such as:

- manufacturer markings

- defects to the die

- typography is correct

- part numbers are accurate and authentic.

Identifying counterfeit components can be difficult as there may be more than one reason behind components failing individual tests. Component manufacturers have been known in the past to make production errors and then remark components themselves. So, not everything that looks suspect, is necessarily a counterfeit device.

However, Powerline uses multiple detection tests to examine incoming components and you stand a far better chance of minimizing the risk of suspect devices entering our supply chain. Powerline also provide our customers, the peace of mind and confidence that when they take the product out of the box, or install it alongside their machinery, it will work first time, error free.